Mobile Accessories Inspection

All-Inclusive – Inspection Service All Over China: $199 per Man Day

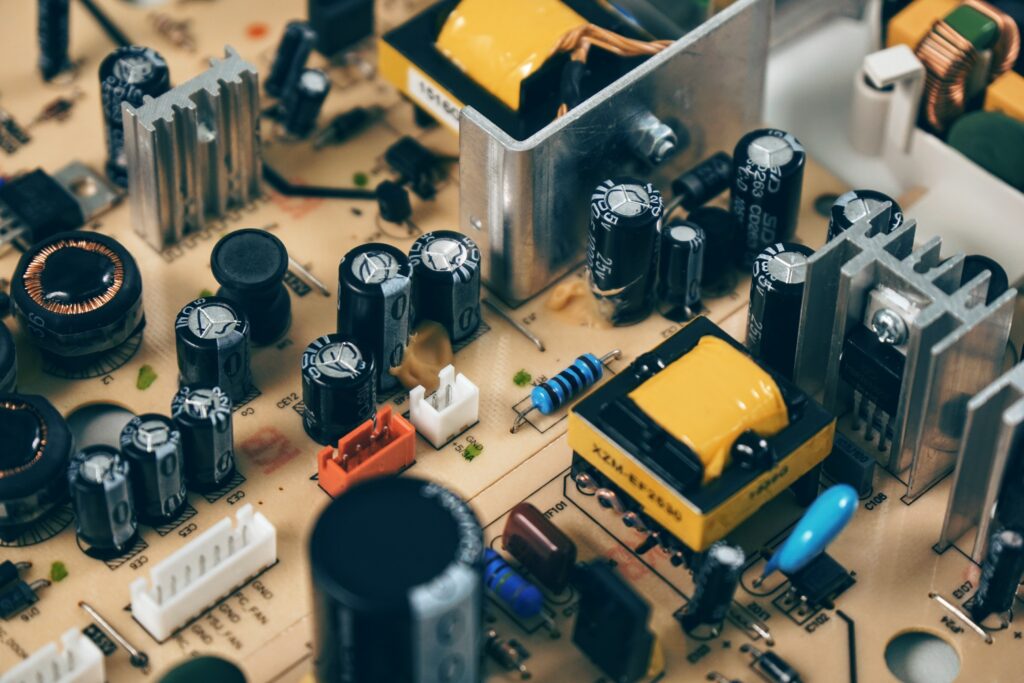

A crucial step in ensuring that your products are free of flaws, safety concerns, and other non-conformances before they are shipped to customers is to inspect your mobile accessories before shipping. Always check the functionality and quality of the workmanship when inspecting mobile accessories.

Checklists For Quality Assurance of Mobile Accessories

Check on appearance and craftsmanship

- A careful inspection for any external flaws.

- Comparing the product’s dimensions, colors, and material quality to the reference sample to determine whether they are in compliance or not.

- Verification of the packaging’s quality as well as the presence of all required labels, signs, and barcodes.

Functionality Test

- Measurements of the chargers’ input and output voltages.

- Analyzing the portable speakers and headphones for sound quality

- Bluetooth connectivity’s strength and range.

- Speed of charging and battery capacity.

.

Common things to look for when evaluating the quality of mobile accessories

1. Battery testing procedures: First, a multimeter is used to test the battery voltage, which should be between 3.8 and 4.2. Next, the surface of the finger and battery stickers are visually inspected for scratches, dirt, and the bulging phenomenon.

2. How to test headphones: First visually check to see if the model headphones stickers are correct if the rusted wire plug is undamaged if the phone will automatically hang up (the automatic hook was a defective product), if the sound is normal on both sides of the headphones, if there is monophonic, single complex, or no sound other phenomena, and finally press the headset button to see if the normal hook-ho is present.

3. Methods for testing the charger: First, visually check to see if there are any scratches on the charger, if the font is incomplete, if there is rust on the USB plug, or if there is a burr phenomenon. If everything looks good, charge the phone to 100% to ensure that the charge is normal.

4. USB data cable test methods include connecting a phone to a computer via a USB cable to check for things like normal USB recognition, rusted batch fronts on USB plugs, type stickers, and more.

5. Film for mobile phones: In addition to the substance, it’s important to comprehend the film’s strength, light transmission, and viscosity. The primary consideration is how well the protective film transmits light.

Inspection and Quality Control Services:

It is frequently necessary to use specialized tools when inspecting mobile accessories.

For this kind of inspection, it is crucial to have inspection guidelines that include thorough descriptions of the product’s features and functions.

The following steps are included in the quality control inspection of mobile accessories:

Overall Evaluation Of The Quality Of The Work

- A careful inspection for any external flaws.

- Comparing the product’s dimensions, colors, and material quality to the reference sample to determine whether they are in compliance or not.

- Verification of the packaging’s quality as well as the presence of all required labels, signs, and barcodes.

A Test Of Functionality

- Voltage readings for the chargers’ input and output.

- Analyzing the portable speakers and headphones for sound quality.

- Bluetooth connectivity’s strength and range.

- Dimensions of the battery and rate of charging.

Because performance issues typically have a systemic nature, thorough function checks are imperative. Therefore, if two out of every ten items have functional flaws, the overall defect rate for 100 items could be close to 20%.

Through a messenger app, you will be able to communicate with the inspector and get real-time images and videos of how the products look, work, and are packaged.

Pre-shipment inspections for all varieties of mobile accessory products are just a few of the auditing and inspection services that HSIN Quality offer in the nations where they are manufactured. These services also include raw material inspection, production line, post-production sampling, and auditing of finished goods. To personalize your supply chain solutions, get in touch with our experts.