Power Tools Inspection

All-Inclusive – Inspection Service All Over China: $199 per Man Day

Power tools are used by carpenters, construction workers, and other manual laborers to help them complete their tasks more quickly. Power tool manufacturers and retailers must abide by strict product safety standards to protect their customers and their brand even though power tools are very useful and also present a number of physical risks that can cause both minor and serious injuries.

Inspection Criteria For Power Tool Standards Of Quality

Standards For Power Tool Safety

Several of the most frequently applied safety standards for power tool inspection are as follows:

Chainsaws, blowers, and grass trimmers are examples of the outdoor hand-held power tools covered by ANSI B175.

Power-driven brushing tools must comply with the American safety standard known as ANSI B165.1-2013.

The cutting-off and crimping tools, tappers, percussion power tools, grinders, sanders & polishers, saws, and compression power tools all fall under the umbrella of the international standard ISO 11148.

Analysis Of Vibrations For Power Tool Testing

These testing techniques measure the amount of vibration produced by power tools like impact wrenches and drills. Consumers are at risk from excessive vibration levels, which are also a sign that a product is broken.

When determining the vibration at the handle of hand-held, portable power tools, refer to ISO 28927, an international standard.

Apply this global standard, ISO/TS 21108, to the specifications and tolerances for the socket interface of hand-held power tools.

Global Market Access Requires IEC 62841 Compliance

IEC 62841 addresses the security of electrical, motor-operated, or magnetically driven tools and includes provisions for portable, handheld, and lawn and garden equipment. For some product categories, it replaces the prior IEC standards, and the US, EU, and Canada have all adopted the harmonized version, which now prevails over the earlier versions. There are a number of deadlines for this recently harmonized standard that will be implemented starting in 2019 and running through 2022.

Checklists for Quality Control Inspections Using Power Tools

- Check of all functions

- Checking barcodes

- A simulation tests

- Check assembly

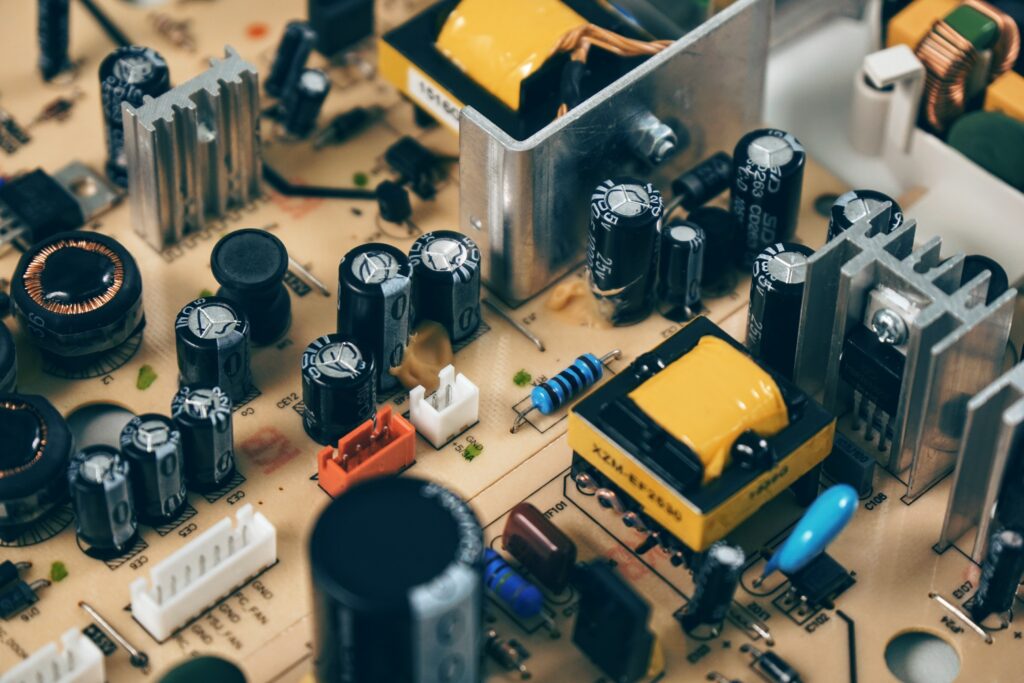

- Internal component/construction inspection

- Rub test (for labels, markings, and logos)

- Drop test for cartons

- A product drop test

- Container stacking test

- Standard function check

- Test for high voltage

- Switch on the test (no load)

- Test for strain relief in power cords

- Check for low-voltage starting

- (Without a load) Speed check

- Checking the power usage or checking the input power and current (without a load)

- Internal examination

- Enter current check

- Test for adhesion

- Noise measurement